Client interview – Ian & Lucie Aldworth.

1. Can you tell us about the work you do?

We operate a agricultural contracting business based in Devon and Somerset offering a crop spraying service, a liquid fertiliser application service, granular fertiliser spreading and slug pellet application alongside soil sampling which covers the whole of the Southwest of England. We cover approximately 30 to 40,000 acres in application each year.

2. You recently purchased a new RB26 what are your initial impressions?

We have recently added a new RB26, which for us after having three RB35’s has been very surprising and an impressive addition to our business. Purchased in September we threw the machine into Autumn work doing over 400 hours in 10 weeks – despite being just 3000lts and 24 m the machine has a three speed transmission with dynamic braking, giving us improved road speed with the safety of braking giving higher output.

This is also our first machine with integrated auto steer which is in daily use every day. Even in tramlines it’s a real time saver, the auto steer is so smooth, accurate and straight yet settled we have engineered a spot sprayer to spray glyphosate to drop in our own tramlines which customers welcome as they are placed accurately and where we want them.

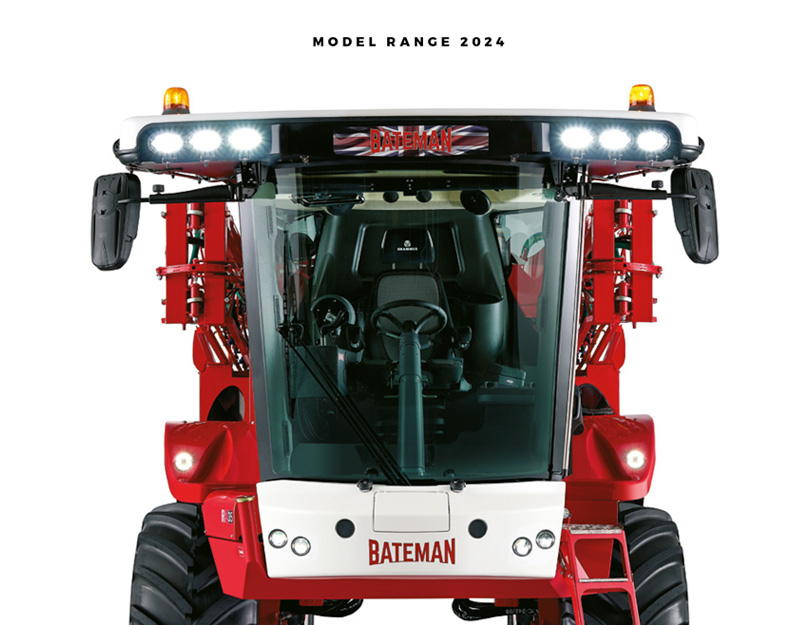

For us the most noticeable features on the new RB26 would be visibility the cab offers, the smooth ride, the road speed, and agility. We also have the additional lighting pack, auto Greaser and auto fill feature – these options are well worth having.

3. How did you find the purchasing experience?

Our purchasing experience as always was relaxed with no pressure and very professional. There are so many options now, gone are the days of choosing either an RB16 or RB25 along with tyre choices.

4. Why did you choose the the RB26?

We chose the RB26 because now with the additional three speed motors it gives us an agile light contractors machine which when organised is incredibly capable of a heavy workload. We have always wanted a more capable smaller machine.

The Michelin 600 floatation tyre option really suits us as we have some narrow lanes to navigate in Devon you’re in the field we push the rear axle out giving us a large footprint which makes a huge improvement on soft ground.

5. Nozzle choices and accuracy?

Nozzle options can be a minefield and are forever changing we first look at coverage followed by drift reduction and opted then for the Billericay pulZar nozzle using 03 and 04 options despite the pressure the fan pattern stays consistent, coverage and drift are good too.

We also run a set of 04 flat fan nozzles with a Syngenta potato nozzle in between each one facing forward,paper testing at 130 to 150 L/ha we think is the best coverage possible but in some conditions may experience slightly more drift. We also run brown and white ESI fertiliser nozzles, which give us a wide enough range to apply nitrogen.

Having 5 way bodies on this machine has enabled us to have these options.

6. Applying liquid fertiliser variable rate through the Agleader

This is the third season applying variable rate liquid nitrogen on some farms, this is growing each and every season the promotion from Agrii and Rhiza along the price of fertiliser correct placement of product is key. The Agleader is fully capable to cope with variable rate Files and it’s very user friendly. We have been applying variable rate granular P&K since 2012.

7. How would you rate the service you receive from Bateman?

Our service from Bateman is incredible – many other mainstream brands could learn a lot from them with the service they offer, it’s clear Bateman not only have the best machine in the UK but probably worldwide. We have had three other brands as second machines but it’s clear the reliability, service, support, value and second-hand residual value put this machine in a league of its own, even the simplicity of the services at 500 hours and the realistic cost of parts make it easy for us to cost and budget.

A huge thank you to Jason and Aideen Bateman and the whole team at Bateman engineering you’ve not only engineered a first class machine you have also helped us engineer our business.

Ian & Lucie Aldworth

Agri Crop services SW Ltd

Want to see a Bateman Sprayer in action on your farm?

Request a visit using the form below.

Would you like to book a demo? Contact us today and arrange for the Bateman Demonstration Team to visit your farm.

Download our latest brochure

Our PDF brochure features details on our full range of self propelled crop sprayers.